Waterjet Cutting

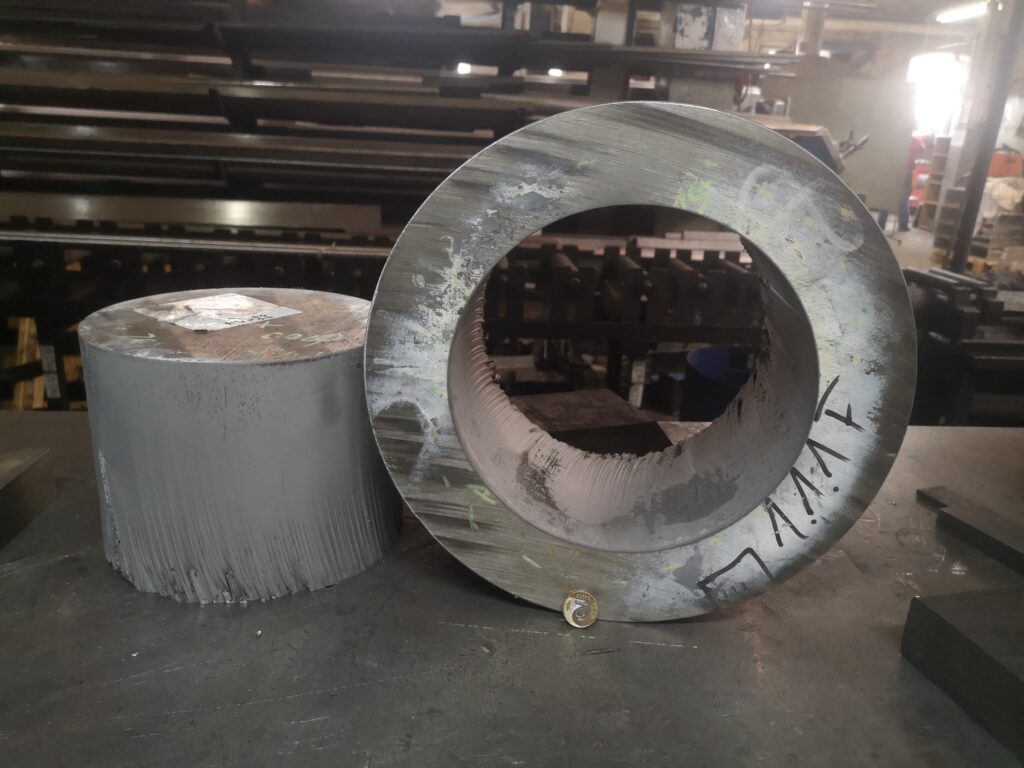

Waterjet cutting is the most versatile method of shaping materials. Without any final processing, we can precisely cut steel, coloured metals, plastics, ceramics, natural stones, wood, and even glass.

The edges of the cut materials are not discoloured, thermally hardened, and do not undergo any structural changes resulting from thermal influence, as in the case of laser processing. The maximum temperature of this process is only 50 degrees Celsius, which enables to process materials without fear of damaging them.

This modern method uses the concentrated energy of the water jet released along with the comminuted abrasive. Pressure up to 4,000 bar is exerted on the material during the cutting process. The diameter of the water jet is at least 0.2 millimetres, and the speed is up to 1,000 meters per second. Waterjet cutting enables to make both a single element and several thousand series in which each element is exactly the same. The entire process is smooth and the achieved accuracies reach up to 0.1 millimetre.

Many different materials can be cut simultaneously with a water jet along with maintaining high precision and refined shapes. The cut is precise, safe and environmentally friendly. We offer professional waterjet cutting services of materials up to a thickness of 150 mm. The table dimensions are 1,600 x 3,010 and the working size is 1,500 x 3,000.

We look forward to working with you.